A ball mandrel is a tool used in pipe bending to support the inside of a pipe during the bending process. It is also known as a mandrel rod or mandrel bar. The ball mandrel consists of a steel rod with a spherical ball at one end, which is inserted into the pipe being bent. The ball helps to distribute the pressure of the bending process evenly throughout the inside of the pipe, preventing it from collapsing or wrinkling.

The use of a ball mandrel in pipe bending is important because it helps to ensure the accuracy and quality of the bend. Without a mandrel, the inside of the pipe can collapse or deform during the bending process, leading to a distorted and unusable final product. The ball mandrel provides support for the inside of the pipe, ensuring that it retains its shape and dimensions during the bending process.

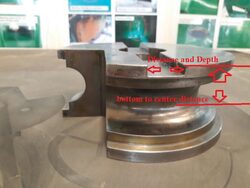

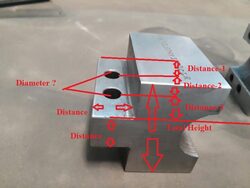

There are several different types of ball mandrels used in pipe bending, each designed for a specific application or material. For example, some mandrels are designed for use with thin-walled pipes, while others are designed for use with thick-walled pipes. Some mandrels are also designed for use with specific materials, such as stainless steel or copper.

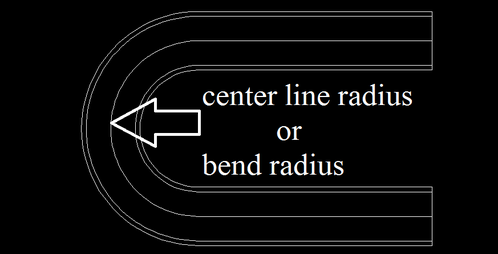

The use of a ball mandrel in pipe bending typically involves several steps. First, the mandrel is inserted into the pipe being bent, with the ball end positioned at the center of the bend. The pipe is then clamped in place, and the bending process begins. As the pipe is bent, the mandrel provides support for the inside of the pipe, preventing it from collapsing or wrinkling. Once the desired bend angle has been achieved, the mandrel is removed from the pipe, and the finished product is inspected for quality.

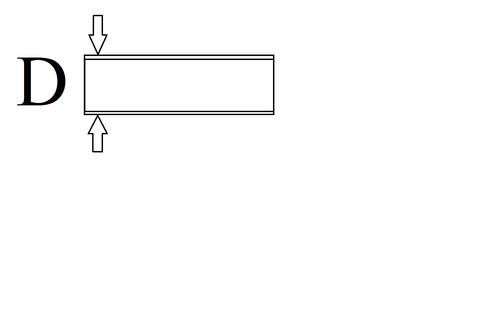

There are several factors to consider when selecting a ball mandrel for pipe bending. These include the material being bent, the diameter and thickness of the pipe, and the desired bend angle. It is important to choose a mandrel that is appropriate for the specific application, as using the wrong mandrel can lead to poor quality bends and potential damage to the pipe.

In conclusion, a ball mandrel is a critical tool in the process of pipe bending. It provides support for the inside of the pipe, ensuring that it retains its shape and dimensions during the bending process. The use of a mandrel helps to ensure the accuracy and quality of the final product, and there are several different types of mandrels available to suit specific applications and materials. When selecting a mandrel, it is important to consider factors such as the material being bent, the diameter and thickness of the pipe, and the desired bend angle to ensure the best possible results.